Need Help With Your Application?

Enrique Francis

[email protected]

678-928-6534

Hi, I’m Enrique Francis, the sales manager for bulk solvents at Chemtronics.

Today I’m going to take you through the different methods of degreasing, and how Chemtronics products can help your operation be more productive, efficient, and most importantly safer.

Chemtronics Product Offering

Solvent degreasers are packaged in aerosol or saturated on wipes for convenience, or in gallons, 5-gallons or larger containers.

Chemtronics offers a wide variety of degreasers for all types of applications, which include manual cleaning, ultrasonic cleaning, and vapor degreasing.

Let’s go through those in more detail.

Manual Cleaning

Manual cleaning involves cleaning parts or equipment by hand. You might use an aerosol or presaturated wipes, or simply immerse parts in a tray of solvent. You can add agitation with wipes or brushes for really difficult soils.

Pay attention to evaporation rate when selecting a degreaser. Fast evaporating solvents, like alcohols, can be efficient. For thick greases or baked out soils, take a look at slower evaporating solvents like with hydrocarbons and citrus oils. They allow more time for the solvent to soak in and break-down the grease.

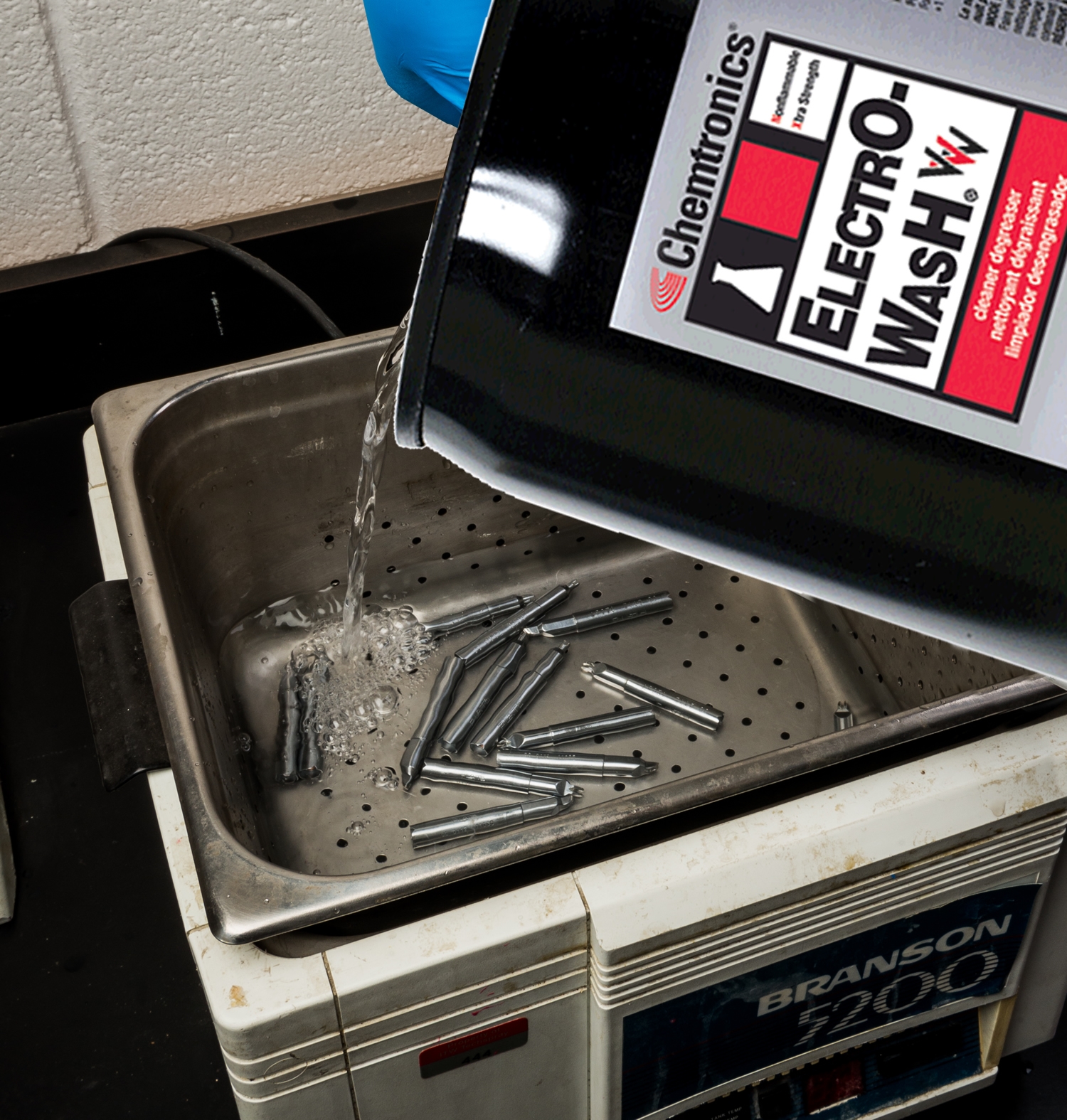

Ultrasonic Cleaning

Ultrasonic cleaning equipment use sound waves to break apart grease and lift it off the part. Ultrasonic equipment usually has the option of heating the cleaning material to increase cleaning performance.

Cross-contamination can be a concern, so change the solvent regularly.

We recommend that you always use nonflammable solvents for ultrasonic cleaning.

Chemtronics Tri-V solvents offer powerful cleaning action, and don’t contain toxic chemicals like nPB.

Vapor Degreasing

Vapor degreasing is the best cleaning process for critical cleaning, like in aerospace and medical implants.

Parts can be submerged in a sump of boiling solvent, which might include ultrasonics and rinsed in solvent vapors.

Specialized azeotropes or near-azeotrope solvents are required to avoid problems as the solvent is boiled and reconstituted repeatedly.

Chemtronics Tri-V solvents are effective in vapor degreasers, and don’t contain toxic chemicals like nPB. They are also perfect replacements for Novec and Vertrel based solvents, which have been difficult to find at times because of supply chain issues.

Qualification Lab

If you are looking for a new degreasing solvent for your facility, we can help you through the selection and qualification process.

Chemtronics offers a state-of-the-art cleaning and analytical services to help you qualify our solvents for your process. We have in-house cleaning equipment including inline, batch, ultrasonic, and vapor-degreasing systems. This equipment allows us to duplicate your production environment.

So you have a friend in the degreasing business! Please contact me with any challenges you’re facing, and we’ll help you be more efficient, productive and safer than ever.