Conformal Coating

Use Konform Conformal Coating for Maximum PCB Protection

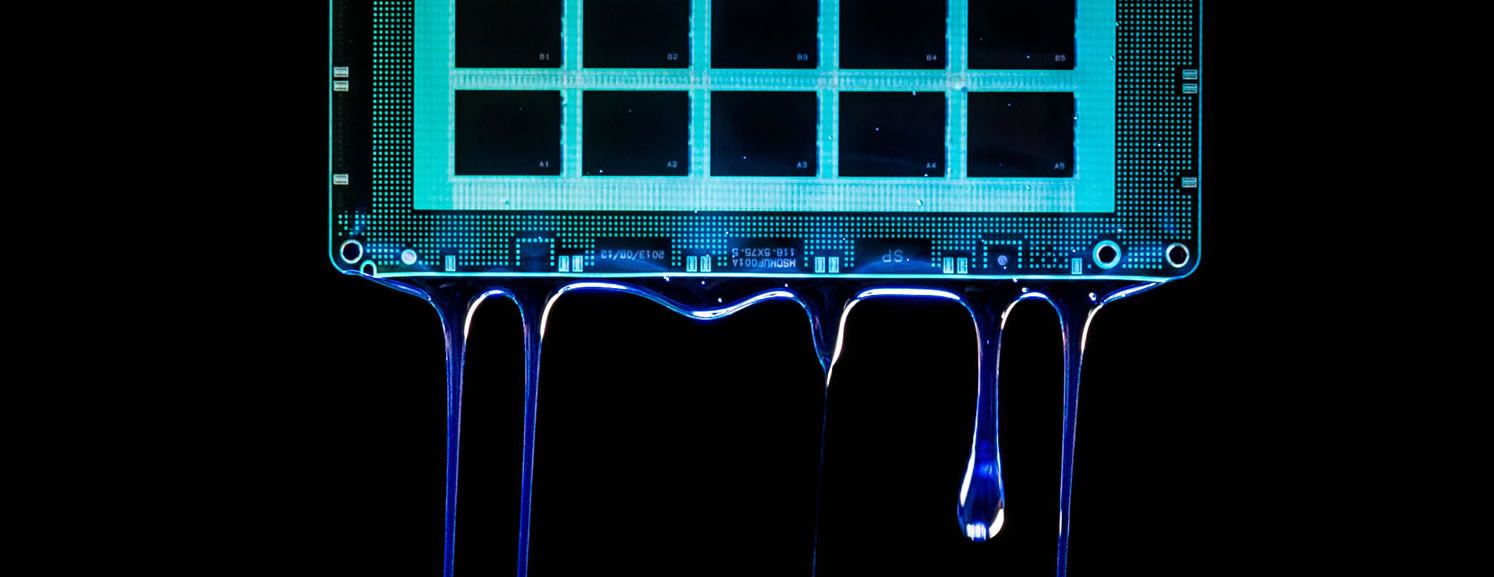

Chemtronics Konform Conformal Coating is used for spray, dip tank, and brush applications. They're engineered for applications in aerospace, marine manufacturing, electrical equipment, instrumentation, and data communication. They protect printed circuit boards, components and flex circuitry from damage. These coatings provide excellent electrical insulation properties that withstand hot and cold operating environments, thermal shock, mold, and fungus.

All Konform conformal coatings contain a UV indicator for improved quality assurance. They offer high dielectric strengths of 1100 volts/mil or more. These tough, transparent coatings will not fragment, chip or crack, thereby providing excellent protection. All are convenient and ready to use — no mixing is required.

All Konform coatings are tested in accordance with the IPC-CC-830 standard to ensure they are well suited for coating sensitive electronics. Konform AR and SR both qualify for ULT746E.<

Konform coatings come in 2 resin categories:

- Acrylic Resin (AR) – Provides fair elasticity and general protection. Recognized for their high dielectric strength, abrasion resistance and ease of removal.

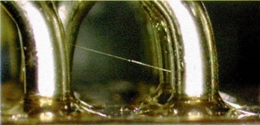

- Silicone Resin (SR) – Provides excellent protection in a very wide temperature range, good chemical resistance, salt spray resistance and are very flexible. Removal can be challenging, requiring specialized solvents and long soak time.

Resin Type

Application Method

Operating Temp

Protective Properties

UL 746

Environmental & Safety