Aviation

Avionics Repair Tools

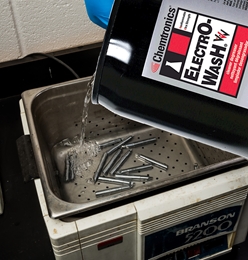

Chemtronics products make avionics repair faster, easier and more accurate, improving equipment reliability even in the most challenging aviation environment. Soder-Wick® and CircuitWorks® board repair products are advanced materials packaged in unique delivery systems. They ensure exacting performance and pinpoint accuracy. Chemtronics products meet all of the technician’s needs for avionics repair — cleaning, protecting and restoring electrical conductivity to circuit boards and components.

Aviation MRO Cleaners

Chemtronics aviation maintenance cleaners improve performance, efficiency and safety for degreasing, contact cleaning, and aircraft surface cleaning.

SAFETY IS THE TOP PRIORITY – Chemtronics degreasers and contact cleaners are ideal replacements for highly toxic solvents like nPB, TCE

Environmental & Safety