Ultrasonic Cleaning

Safe & Powerful Solvents for Ultrasonic Cleaning

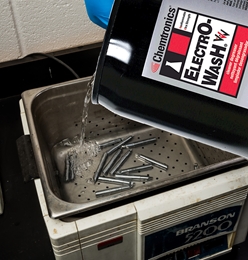

When removing tough soils like baked-on flux residues or heavy industrial greases, ultrasonic cleaning can get the job done faster and more consistently than most other methods. Ultrasonic cleaning uses equipment to send ultrasound to create high energy mini-implosions within the soil, creating intense agitation.

Your choice of cleaning material will make a huge impact on cleaning effectiveness and the time required. When choosing an ultrasonic cleaner, pay close attention to…

- Solvency, or the ability of the cleaner to breakdown and dissolve the soil.

- Surface tension, which affects how well it can get into tight areas. The lower the surface tension, the better it will be able to penetrate under low-standoff electronic components, drill holes, and other hard-to-reach areas.

- Density can have a minor impact on how quickly the sonic waves travel through the liquid, and the amount of cavitation. Lower density materials require less energy to create the sonic waves.

- Nonflammable cleaners are the safer choice, especially when the cleaning material is heated.

- Avoid highly toxic solvents that are commonly used, like TCE, nPB, Perc and Methylene Chloride. With enough exposure, these chemicals can cause cancer, kidney and liver failure, and other serious health problems.

- Water-based cleaners generally need to be rinsed, but solvent cleaners usually evaporate off without leaving residue behind.

- In some regions more than others, you need to watch out for environmental issues like volatile organic compounds and global warming potential.

Plastic Sensitivity(Choose One)

Soil Type / Application

Flammability

Environmental & Safety

Flux Type