Max-Kleen Tri-V

Extra-strength, nonflammable heavy duty electronics cleaner for replacing n-propyl bromide

The Ultimate n-Propyl (nPB) Replacement

Max-Kleen™ Tri-V removes of all types of soils from

Removes oils, greases, silicones, refrigerant oils, fluxes, adhesives and other common industrial contaminants. Used for cleaning medical instruments, implants and other devices including orthopedic implants, monitoring devices, oxygen and gas lines. This solvent can be used as a carrier fluid like for silicone-based lubricant coatings.

The Max-Kleen™ Tri-V™ Advantage

Max-Kleen Tri-V is a true azeotrope, so both the liquid and vapor phases maintain the same composition. It acts as a single component product, so will not fractionate as it boils. This avoids any performance changes as it is used over a long period of time, or is run through a separate reclamation unit.

Specifications: Meets Airbus UK ABR 9-0140, Boeing BSS7432, GE SM2369-10, report #Q40358, GE 70-16-80 Hot Corrosion Test, ARP1755B Stock Loss Test

CLICK HERE FOR CLEANER DEGREASER SELECTION GUIDE

Features & Benefits

- Quickly removes all types of tough soils including oxidized oil and grease

- Best product for electronic applications

- Dielectric strength of >30 kV (liquid)

- Full azeotrope

- Does not contain n-propyl bromide, trichloroethylene, perchloroethylene, HAP’s, or any ozone depleting compounds

- Nonflammable, no flash point

- Stabilized for metals such as aluminum, magnesium, titanium, and brass

- Noncorrosive, safe for sensitive metals

- Leaves no residue

- NSF Registered - Nonfood Compounds / Code K1 and K2

Applications

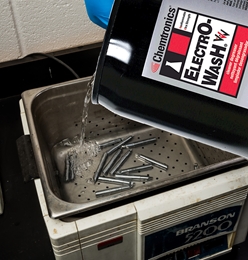

- Removal of soils from electronic circuits

- Cleans contacts, relays and switches and fuse blocks

- All repair and maintenance cleaning including: electronic switches and logic controllers

- Medical instruments like monitoring devices, oxygen and gas lines

- Orthopedic implants

...and act as carrier fluid like for silicone-based lubricant coatings.

Vapor Degreaser Setting Guidelines

- Boiling point – 108°F / 42°C

- Boil sump temp set – 117°F / 47°C

- High solvent temp set – 126°F / 52°C

- Refrigerant high temp set – 99°F / 37°C

- Vapor pressure @ 77°F / 25°C – 405 mm Hg

As with all vapor degreaser equipment and processes, observe all safety precautions, guidelines and operating rules associated with these units. Failure to do so may put operations personnel at risk. Avoid excessive vapor losses, loss of refrigeration, excessive boil sump heat, etc. Make sure all equipment is operated in accordance with the manufacturer’s guidelines and instructions. If in doubt, contact your manufacturer immediately.

Chemtronics Solvent Cleaner Brochure - featuring Tri-V Solvents

Tri-V

Technical papers:

Tri-V™ Cleaning Solvent Performance Evaluation

Reducing Exposure to Toxic Cleaners with Replacement Solvents