Board manufacturers, wishing to improve the appearance of the boards, need a material that can easily repair any chips or scratches in the permanent resist coating, improving the appearance of the finished board. Chemtronics offers two solutions: CircuitWorks Overcoat Pens and CircuitWorks Epoxy Overcoat.

Permanent solder resist (also called overcoat and mask), the colored (most commonly green, but can be other colors) background surface you see on most circuit boards, is a very tough, durable epoxy or epoxy-acrylate coating. Resist coating is usually a one or two-part liquid that is coated onto the FR-4 and copper surfaces of the PCB by a variety of methods, and then cured. Resist material also comes in a dry-film form, which is applied to the PCB surface using heat and pressure in a lamination process. Such resist coatings are permanent and are not easily removed, but they can become chipped or scratched during shipping and further processing.

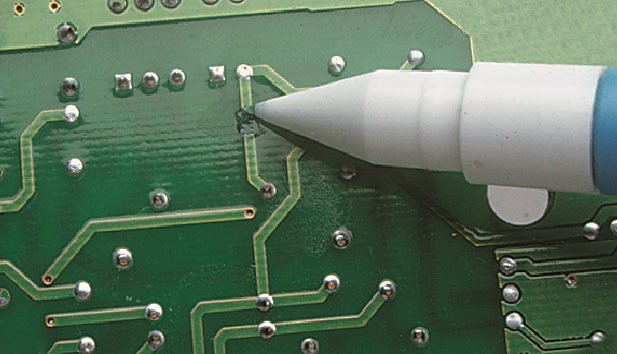

CircuitWorks Overcoat Pens can be used to cover chips and scratches in the permanent resist layer, returning the board to its original appearance. The Overcoat material is a highly effective acrylic conformal coating provides excellent protection against shorts, moisture, abrasion, fungus, and other environmental hazards. Overcoat Pens allow for easy repair of solder mask in prototype, manufacture and repair of circuit boards. With the fine drawing tip, you simply draw coating over the repair area.

CircuitWorks Overcoat Pens are commonly used in conjunction with CircuitWorks Conductive Pens. A trace or pad can be repaired, reestablishing continuity with conductive ink, and they coated with the Overcoat material. This protects the repair from outside elements like moisture, and prevents arcing and shorts with the coating’s high dielectric strength.

Overcoat Pens are available in a variety of colors to better match the original PCB, including: green (part #CW3300G), clear (CW3300C), and blue (CW3300B). Black (CW3300BLACK) and White (CW3300WHITE) are also available to repair PCB markings or cover component identification for security or IP protection.

It should be noted that CircuitWorks Overcoat Pens should be the final step in processing the board. The Overcoat material is a modified acrylic conformal coating not an epoxy resist material, so it does not have the same properties of durability and permanence as a permanent solder resist. It will decompose or char at temperatures above 270°F (132°C), and therefore should only be applied to the board after all soldering has been done.

When soldering is required after the repair has been done, Chemtronics offers CircuitWorks Epoxy Overcoat (CW2500). It is a permanent green coating formulated to protect circuit traces before being exposed to reflow conditions. Epoxy Overcoat two component, 100% solids epoxy that is engineered specifically for high temperature resistance, used for electronic circuit and component protection.

CircuitWorks Epoxy Overcoat forms a chemically inert coating that seals out moisture and environmental contaminants, minimizes thermal shock and prevents corrosion, oxidation, and abrasion. The Epoxy Overcoat easily withstands brief exposure to high temperatures found in normal wave and reflow applications.

CircuitWorks Epoxy Overcoat can withstand service temperature between -55°F and 600°F (-48°C and 315°C), and meets IPC-7721.2.4.1 requirements.

For more information, contact a Chemtronics application specialist at [email protected] or 770-424-4888.