By Chris Perabo, guest contributor

Electromagnetic Interference (EMI) and Radio-Frequency (RF) interference are two types of interference that negatively affect electronics. In some cases, even low exposure to EMI/RFI could cause sensitive electronics to degrade their performance or completely malfunction. It is possible to electromagnetically shield these electronics and conductive paints and inks open up new possibilities to either create an EMI shield or to repair an existing one.

EMI/RFI and the need for Electromagnetic Shielding

Though EMI and RFI are often used interchangeably, Radio-Frequency (RF) refers to a specific subsection of the Electromagnetic (EM) spectrum, namely the frequency range dedicated to radio frequency transmission. As can be seen on the EM spectrum diagram, RF frequency starts from as low as 3 kHz to as high as 30 MHz.

EMI/RFI is by definition a disturbance that can either occur naturally in nature as with lightning, solar flares and auroras or be generated by man-made sources, the largest source of which is from legally operating transmitters or cellular networks.

Electromagnetic shielding is the prevention of unwanted EMI or RFI from causing electronics to have their performance degraded or to malfunction. Typically, the shielding is applied to the electrical enclosures to isolate specific electrical devices from their surroundings. This is done by reducing the electromagnetic field in the space by blocking the field with barriers made of conductive materials.

Electromagnetic shielding is most effective in the higher frequency range between 30 to 100 MHz. Since the lower end of this range is the upper end of the RF range, when we refer to using conductive paints for EMI/RFI shielding, it refers more specifically to the upper end of the RF frequency range or other EMI in this 30 to 100 MHz range.

Conductive paints and other materials used to shield EMI and RFI?

The amount of reduction of the electromagnetic field (and hence the amount of electromagnetic shielding provided), is dependent on many factors including:

- The frequency and intensity of the electromagnetic interference (EMI)

- The conductivity of the barrier material1

- The type of shielding material used

- The size and type of openings in the EMI shielding material

- The quality of the shielding material

- The continuity of the shielding material

Among the various types of materials used for EMI shielding, it really depends on the application. In the case of shielded cable, aluminum foil or a wire mesh are very common. In the case of military devices or other very high end electronics applications, various forms of metal are used including sheet metal, foam metal and metal screen.

However, in the case of consumer electronics, these large bulky metal structures are heavy and cumbersome. This is a typical application for CircuitWorks® Conductive Paint (part #CW2205). Using an inexpensive plastic enclosure, CW2205 is used to coat the inside of the case with a thin, but highly conductive silver layer.

Repair of painted plastic shielded enclosure

CircuitWorks Conductive Paint is a single component, silver-filled polymer that dries in minutes at room temperature, creating nearly-instant, highly-effective EMI shielding. With a high silver concentration, the conductive paint has excellent electrical conductivity, contributing to best-in-class EMI shielding in its category for the same thickness.

Using CircuitWorks Conductive Paint for EMI/RFI Shielding Repairs

In addition to creating new EMI shielding components, conductive paint can also be used to repair existing EMI/RFI components.

In the case of metal screen and wire mesh, it is important that the holes in the screen or mesh are significantly smaller than the wavelength of the electromagnetic radiation being kept out.

As can be seen in Figure 1, a damaged screen mesh can have holes much larger than intended, easily doubling or more the hole size. In such cases, EMI can cause significant disruption leading to reduced performance or complete malfunction.

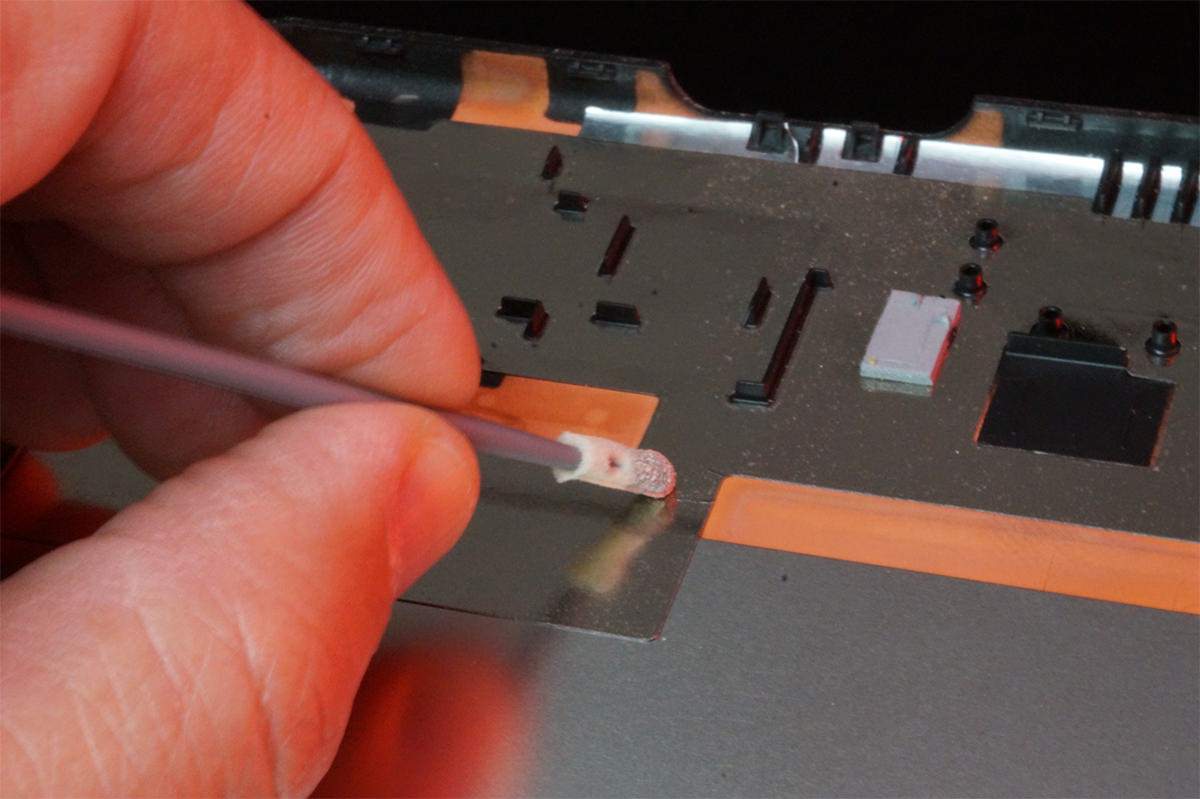

The goal of such mesh designs is to maintain a consistent hole pattern with a conductive material to ensure electrical continuity. Such a mesh can be repaired by restoring the hole pattern using polyimide tape and CircuitWorks Conductive Paint.

Simply apply the polyimide tape to the inside of the mesh and carefully restore the mesh pattern with the CW2205. It is important to ensure that the contact is maintained between the mesh and the conductive paint. A second layer of polyimide tape can be applied to the opposite side for increased durability. Since the polyimide tape is invisible to electromagnetic fields at these wavelengths, the polyimide tape can remain and the EMI shield is restored.

Figure 1: Damaged screen mesh can be repaired with polyimide tape and conductive paint.

Another common situation is that the aluminum foil inside shielded cable is damaged. Similar to the case above, this will cause a loss of continuity and could again allow electromagnetic interference. A simple repair in this case is to repair the hole or tear with polyimide tape and then use the CircuitWorks Conductive Paint to paint the tape and restore continuity.

For more information, go to www.chemtronics.com to learn more about our whole range of conductive inks, paints and epoxies including our CircuitWorks Conductive Paint. If you have any other questions about using conductive paint to maximize high frequency shielding, please feel free to leave a comment below or don’t hesitate to contact Chemtronics technical support at [email protected] or 770-424-4888.

Chris Perabo is an Aerospace Engineer, entrepreneur and frequent blogger based out of the Netherlands.

1C. Morari et al, "Electrical Conductivity And Electromagnetic Shielding Effectiveness Of Silicone Rubber Filled With Ferrite And Graphite Powders" (Progress In Electromagnetics Research M, Vol. 21, 2011)