Proper cleanroom wiping techniques are essential to maintain the cleanliness and integrity of the controlled environment. Cleanrooms are used in various industries, such as pharmaceuticals, electronics, aerospace, and biotechnology, where even the tiniest contaminants can be detrimental to the processes or products being produced. Here are some key steps and guidelines for cleanroom wiping:

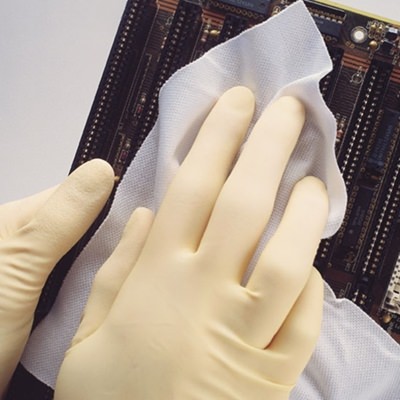

- Use the right materials: Select appropriate wiping materials that are compatible with the cleanroom environment. Common materials include non-woven wipes, microfiber wipes, and polyester wipes. They should have low particle generation, low linting, and be free from contaminants.

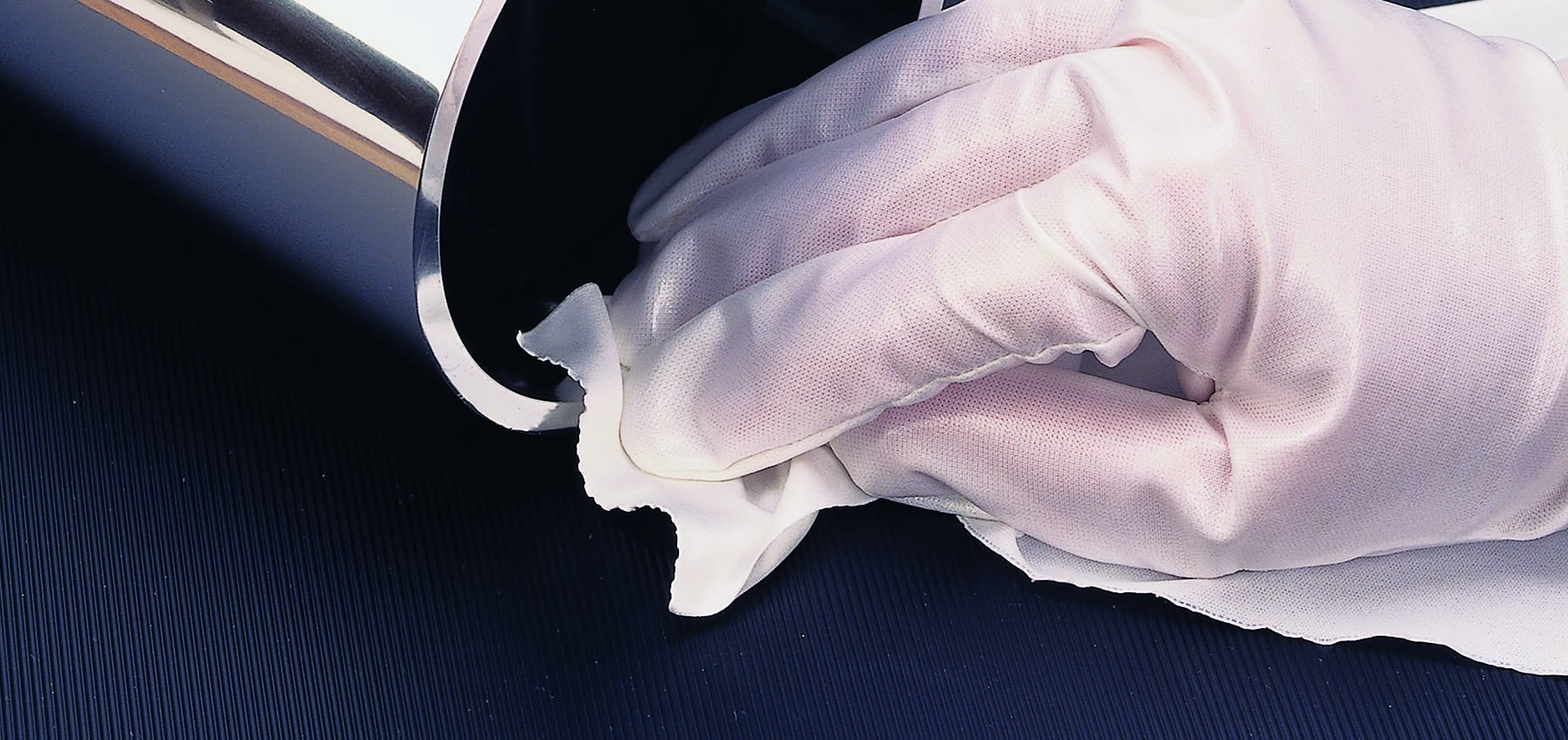

- Wear proper cleanroom attire: Before starting any wiping procedure, ensure you are wearing the appropriate cleanroom garments, including gloves, a gown, and a face mask, to prevent the introduction of particles and skin oils.

- Prepare the wiping solution: If a wiping solution is necessary, use a cleanroom-approved cleaning agent. Some cleanrooms use isopropyl alcohol or other specialized cleaning solutions. Ensure the solution is properly diluted according to the manufacturer's recommendations.

- Follow a wiping pattern: Adopt a systematic wiping pattern to ensure complete coverage of the area. Start from the cleanest area and work towards the dirtier zones. Avoid cross-contamination between different surfaces.

- Use gentle pressure: Apply only light pressure while wiping to avoid damaging sensitive surfaces or releasing particles into the air.

- One-directional wiping: Whenever possible, use one-directional wiping, moving from one side to the other, to prevent particles from being redistributed.

- Change wipes regularly: Replace wipes frequently to avoid spreading contaminants. Dispose of used wipes properly according to cleanroom protocols.

- Avoid wiping overhead surfaces: Wiping overhead surfaces can release particles downward, contaminating lower surfaces. Use alternative cleaning methods for these areas.

- Follow cleanroom class-specific protocols: Different cleanrooms have different cleanliness classifications (ISO Class 1 to 9, for example), each with its specific protocols. Ensure you follow the appropriate procedures for your cleanroom class.

- Perform regular training: All cleanroom personnel should receive proper training on cleanroom wiping techniques to ensure consistency and effectiveness.

Always adhere to the cleanroom's specific Standard Operating Procedures (SOPs) and guidelines while performing any cleaning tasks. Proper cleaning and wiping techniques are critical to maintaining a controlled environment and ensuring the quality of products or processes within the cleanroom.